Description

Feuling HP+ Oil-Cooled & Water-Cooled Oiling System

The Feuling HP+ Oiling System delivers improved oil pressure, increased oil volume, and better oil scavenging for Harley-Davidson® Twin Cam and Milwaukee-Eight® engines. As a result, engines maintain more stable oil control under load. Because of this, riders see cooler operating temperatures and reduced wet sumping.

Fitment

-

2007–2017 Twin Cam models

-

2017–newer Milwaukee-Eight® engines, including oil-cooled and water-cooled versions

Important: You must check crankshaft runout before installation. Runout must measure .005″ or less.

For this reason, Cycle Solutions Inc. tests crankshaft runout on every installation we perform. In addition, we strongly recommend this kit for Milwaukee-Eight engines to help reduce wet sumping.

Performance Improvements

This oiling system corrects common factory oiling limitations. First, it increases oil pressure where the engine needs it most. Next, it improves oil return scavenging to keep excess oil out of the crankcase. Because these changes work together, the engine runs smoother and quieter.

Key improvements include:

-

Increased oil pressure and oil volume

-

Improved oil flow to critical engine components

-

Better oil scavenging and crankcase control

-

Reduced wet sumping, blow-by, and oily air cleaners

-

Lower engine and oil temperatures

Testing shows the following gains:

-

Up to 42% more scavenge volume

-

Up to 68% more oil volume to the crankshaft and rod bearings

-

15–25°F lower engine temperatures

-

15–30°F lower oil temperatures

-

10–30 PSI increase in oil pressure

-

Dyno results show 2 HP and 2 ft-lbs of torque gains on Milwaukee-Eight engines

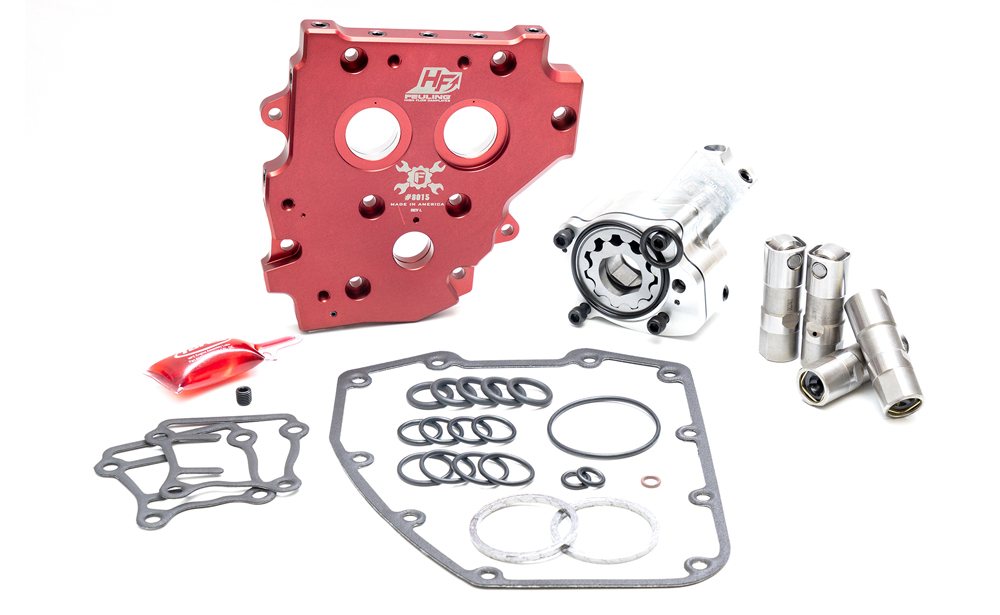

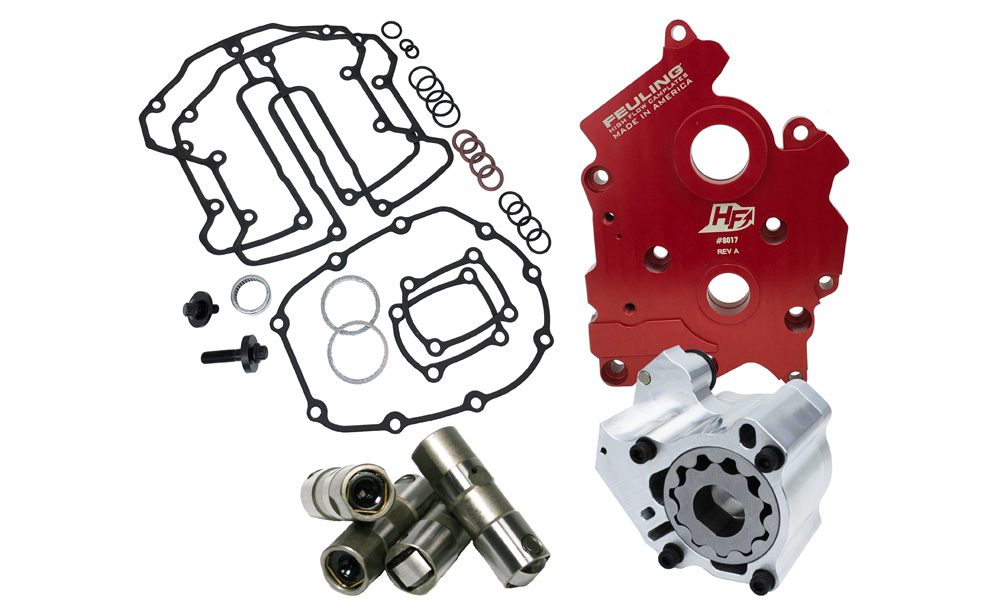

Kit Components

Feuling packages all required components under one part number. Because each part works together, installation remains straightforward and oiling performance stays consistent.

The kit includes:

-

High-flow billet camplate machined from 7075 aluminum, which provides greater strength than stock

-

High-volume billet 6061 aluminum oil pump

-

HP+® hydraulic roller lifters

-

Cam installation kit

-

Cam bearing

-

Cam and crank bolts with washers

-

Engine and fastener assembly lube

Additionally, Feuling bench tests every oil pump. The pressure relief valve seats at a minimum of 30 PSI, while full pop-off occurs between 55–60 PSI.

Oil Pump Specifications

Feuling designs oil pump specifications around each engine type. For this reason, oil delivery remains consistent across different Milwaukee-Eight configurations.

-

Milwaukee-Eight Twin-Cooled™ engines:

-

30% more pressure gear volume than stock

-

53% more scavenge gear volume than stock

-

-

Milwaukee-Eight Oil-Cooled engines:

-

27% more pressure and scavenge gear volume than stock

-

As a result, engines maintain stable oil pressure across a wide RPM range.

Optional Upgrades

Riders can add an optional Feuling ARP high-flow camplate and oil pump fastener kit for added strength. Because ARP designs these fasteners specifically for Feuling components, they provide improved clamping force and sealing.

-

Heat-treated ARP® 8740 chromoly steel bolts

-

Precision-rolled threads for consistent torque

-

Wide flange design for even load distribution

-

Tensile strength rated at 170,000 PSI

-

Made in the U.S.A.

Important Notes

-

Optional ARP bolt kit (#8022) available (do not use washers)

-

Block-off plate #0932-0036 required when using gear-drive cams

-

Milwaukee-Eight engines must verify front exhaust lifter clearance

-

Testing shows up to 50% reduction in engine sump oil level

-

Made in the U.S.A.